Explore Our Products

Spare parts

Discover our extensive selection of spare parts designed to keep your equipment running smoothly. We ensure availability without delay, offering competitive prices and a comprehensive list of parts to meet your needs. Trust us for reliable sourcing and prompt delivery of essential components, supporting the longevity and efficiency of your operations

Rope guide

Made up of two halves and easy to replace, rope

guides are designed to guarantee smooth rope

reeving and minimize wear.

“CBA” VERSION

This is the most common crab unit

configuration, featuring a compact

size trolley with two driven wheels.

These flanged wheels are connected

through a shaft and are powered by a

parallel shaft gearmotor

“CMR” VERSION

This is the traditional version of the

low-headroom hoist units, with the

hoist off-centered and balanced by

means of a ballast on the other side

of the beam.

The CT movement is achieved

through two parallel shaft gearmotors.

“CBS” VERSION

In this version, hoist and trolley

are identical to the CBA version,

only assembly differs. This

interchangeability allows to change

the configuration of the crab unit

in case of need (typically when

rail-to-roof clearance is less than

expected

“CRO” VERSION

This is the new configuration OMIS

is employing for their low-headroom

hoist units, and it will soon replace all

the previous CMR versions.

Basically, the ballast has been

replaced by contrast wheels running

on the bottom plate.

The CT movement is achieved

through one parallel shaft gearmotor

Drum

The drum is accurately machined rom a thick steel

tube. It is set in motion by the slow shaft of the

gearbox through a convex grooved coupling to allow

slight oscillation without producing additional stress.

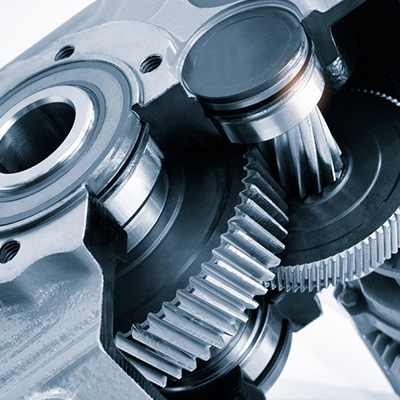

gearmotors

e closed, gearboxes are life-time lubricated with grease.

High mechanical efficiency is ensured by accurate controls during

the assembling phase.

Motors

are of short-circuited type. They feature protection IP55 and

insulation class F.

The possibility to match each gearbox with different motors allows

several LT and CT speeds.

FOOT MOUNTED

Given the particular rectangular

shape, the OPE hoist can be easily

integrated into different types of

trolley frames, as it can be connected

from all four sides.

Load cell

The load cell is a strain-gauge device enclosed in

the fixed-end pin, and it is connected to an electronic

card where two load thresholds can be set up in to

prevent hoist overloading in accordance with the

European specifications.

Electrical Panel

The OPE hoist

Pendant push-button station

Hook-block

Hook is made from high-resistance forged steel and

is equipped with a spring latch. Covers guarantee

against accidental contacts with all moving parts

such as sheaves and rope.

Limit switch

To prevent dangerous situations, OMIS hoists

are equipped with an emergency limit switch that

restricts the vertical lift. It consists of a micro-switch,

mechanically operated by the guide ring, that acts on

the control circuit.

END CARRIAGES

OMIS offers a wide range of end carriages for single

and double girder bridge cranes, for hook capacities

up to 60 tons

open barrel hoist

OMIS drive units have been developed to meet the specific needs

in the material handling market. They are characterised by graduality

of starting and slowing down. They also offer smooth and noiseless

running. The use of high-quality materials and the constant control of

all components in every production phase, allow great reliability.

OMIS drive units ensure low maintenance costs as they have been

designed to suit the most severe operative conditions.